Rebar is frequently a standard steel bar or block that's generally employed in bolstered concrete and bolstered masonry constructions. These rebars will often be generated from carbon metal and should be recounted as reinforcing metal or simply just reinforcement. Underneath Structural BIM Companies Rebar detailing can be a discipline of making fabrication or store drawings of steel reinforcement for the design system. The internet site fabrication drawings that come about for being produced determined by style drawings for reinforcing steel are Rebar In depth drawings. Engineers and Architects make design and style drawings to supply the necessary strengths depending on the rebar detailing that gives diameter, bar styles, quantities, volume of bars to facilitate the site for keeping away from delays and wastage therefore dashing your total construction method.

Each rebar is in depth representing a shape, length, and diameter In line with the necessities within the layout drawing. The Rebar placement will be shown intimately which indicates the concrete cover, correct spot, and Specific way of placement if wanted. The rebar aspects and bar bending schedules can have bar diameter, bar notation, the amount of bars, weight from the bars, and volume of Just about every bar in addition to mentioning the overall pounds for your overall list of bars put Within the drawing. Throughout the preparation of rebar information, the inventory lengths of bars are saved in look at to make certain there is absolutely no wastage through the product.

Rebar Detailing and Reinforcement concrete detailing can now be modeled and intended in three-dimension utilizing the 3D Modelling technologies like BIM Modelling Providers. The specialized rebar detailing computer software like Rebar CAD and AutoCAD helpful for this intent may possibly enable every single member while in the structural engineering to rearrange types, doc, monitor, and make In general Handle.

Having understood principle thought of rebar detailing a bit of structural BIM modeling, why Will not we make an effort to perspective the significance of it in the overall design system is. Some from the causes are:

Great importance of Rebar detailing in Structural BIM Modeling

When 2nd drawings and bending schedules are usually developed and presented, the 3D product is likewise issued to Anyone they associates starting from the consulting engineer and contractor departments into the steel fixers which may be on the wander-out on-web site. The combination of Individuals two turn into In particular beneficial for site personnel the place website limitations or congestion of reinforcements continue being unknown right until you'll find reinforcement and fixation on site. For every single bar, the whole posture of correcting is revealed throughout the 3D model along with any hindrances or obstructions.

Producing detailing reinforcements in 3D about the 2D process is don't just more rapidly but modeling rebar in a very 3-dimensional ecosystem helps clear away clashes. Although modeling it's attainable to visualize if any from the bars do not resolve having a determined spot, thus establish these clashes from the rebar drawings. There may be the facility to look at the reinforcement in comprehensive element being a precise depth illustration in advance of it's staying requested in the fabricator and sophisticated cages are assembled off-website.

When you've the correct rebar detailing Answer offered, a robust and correct reinforcement product can be carried out by importing structural calculations through the structural Investigation system. With Automation associated the alterations are simply mirrored inside the 3D rebar detailing in conjunction with vital updates to drawings and schedules quickly when changes are created somewhere else not like obtaining to accomplish manual modifications to 2nd sections and sights.

In place of determined by manual input from paper schedules, the rebar fabricator can extract information specifically from your product to the equipment. The concrete pours might be properly-described inside the model with other details like portions and volumes to be sure additional accuracy in handling material deliveries. This will permit higher Handle and lead to fewer wastage and lower in All round prices.

Obtaining 3D website detailed digital types is not going to prohibit the ability which has a solitary-section like that Together with the engineering and detailing phase but is usually applied out of all phases. Getting reinforcement entirely modeled in 3D, the contractor is assured that it will easily suit into regions if the time arrives for it to become set on-web page. The information out of your model may be used in the field to allow for contractors to carry out a model-centered format by making use of robotic total station devices As well as tracking rebar and materials and identifying locale They are going to be expected.

Fixers present on-web-site seems to be inside the product atmosphere for the rebar detailing to correctly have an understanding of its software, i.e. what's expected when and where in contrast to depending upon their interpretation of conventional 2D drawings.

The structural engineers can easily plus much more swiftly deliver style reports, schedules, and drawings while in the 3D product compared with 2D layouts, thus improving design performance. There exists a lot more precision on value projection determined by the rebar quantities produced out of your 3D design due to the fact They're more reputable in contrast to second drawing get-offs. Not merely this the portions are wholly traceable, enabling comparisons and checks to generally be executed easily.

Using these explanations, we could conclude that Rebar Detailing a self-control of Structural BIM Modelling Services is just one from the important requirements to the Total results While using the challenge daily life cycle. To summarize, possessing Rebar Detailing the rebar contractor can give consideration to generating rebars there are going to be no need to estimate reinforcement demands for procurements at the web page because of effective 3D models. The product will depict the prerequisite of anchors and laps inside of drawings therefore making sure style and design adequacy Besides reducing wastage. The overall waste and time delays are lessened at the website mainly because each from the shape drawings can be available. According to this data the bars might be easily fabricated based on the designs and variety of bars essential.

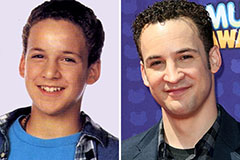

Ben Savage Then & Now!

Ben Savage Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!